1. PROTECTION FACTOR

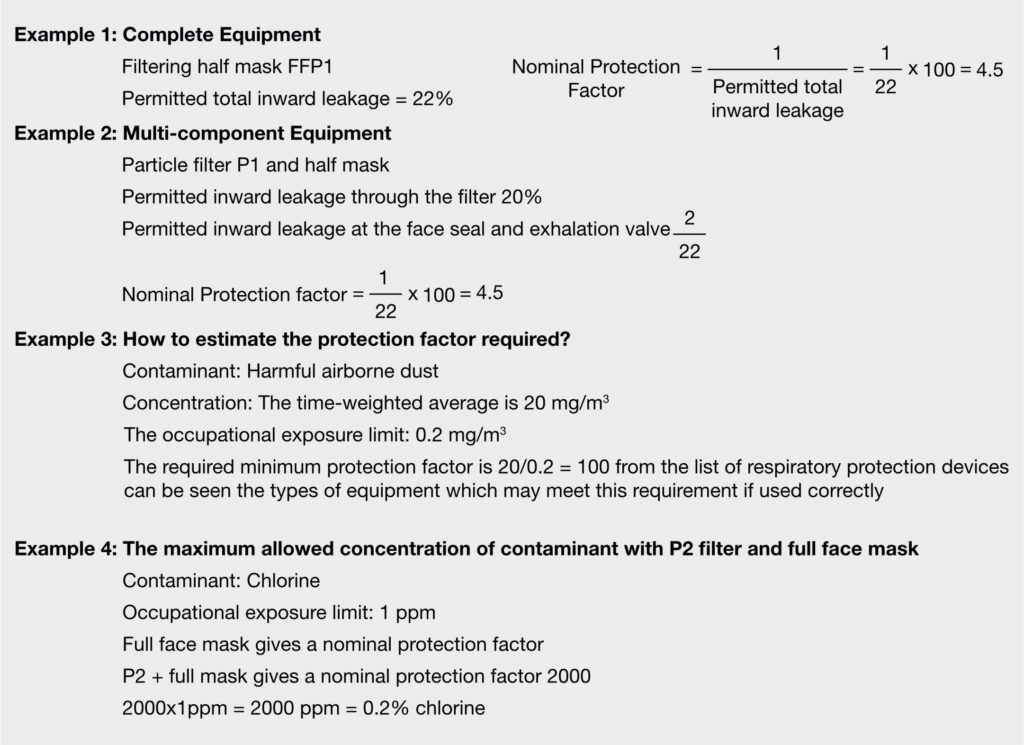

You should aim at reducing the concentration inside the respirator to below any applicable occupational exposure limit (OEL). RPD uses a system called Assigned Protection Factor (APF), the factor by which the equipment reduces the contaminant concentration. An APF of 4, for example, means that the contaminant concentration will be reduced by a quarter. Choose the equipment that has an APF that exceeds the OEL, leaving a margin for equipment error and other factors.

Face fit for the wearer is critical as the face-fitting range relies on a tight face fit to be effective. Facial features such as scars and beards, as well as the shape and size of the wearer’s head and face may affect the fit. A formal fit test is essential.

Fit testing of all negative or positive pressure tight-fitting facepiece respirators is required prior to initial use, whenever a different respirator facepiece is used, and at least annually thereafter. An additional fit test is required whenever there are changes in the user’s physical condition the could affect respirator fit (e.g., facial scarring, dental changes, cosmetic surgery, or an obvious change in body weight). The employee must be fit tested with the same make, model style, and size of respirator the will be used.

Refer to IS 9623:2008 & IS 8347:2007

Respirators with replaceable filters are reusable, and a respirator classified as disposable may be reused depending upon the intensity of particulate matter in the atmosphere. All filters must be replaced whenever they are damaged, soiled, or causing discomfort to the wearer (e.g. increased breathing resistance). Before each use, the exterior of the filter material should be inspected. If the filter material is physically damaged or soiled, the filter should be changed (in the case of respirators with replaceable filters) or the respirator discarded (in the case of disposable respirators). Always follow the user instructions provided by the manufacturer. Employers must develop standard operating procedures for storing, reusing, and disposing of respirators that have been designated as disposable and for disposing of replaceable filter elements.

2. N95 RESPIRATORS

The National Institute for Occupational Safety and Health (NIOSH) is U.S. government agency responsible for the certification and approval of responsible for the certification and approval of respiratory protective devices for occupational use. The authority is granted to NIOSH in accordance with conditions and standards established in Title 42 of the Code of Federal Regulations (CFR), Part 84.

It is the employer’s responsibility under OSHA’s respiratory protection fit testing requirements. It’s important to remember that using a respirator that fits you properly protects your health and safety. As per OSHA reference, Program administrator is responsible for the Fit test.

ANNEX H-CHECKLIST FOR RESPIRATOR PROTECTION PROGRAM

Yes, for Filtering Facepiece Respirators that must be fit tested prior to use, the following Occupational Safety and Health Administration (OSHA) reference must be included in the user instructions:

Before occupational use of this respirator, a written respiratory protection program must be implemented meeting all the local government requirements. In the United States, employers must comply with OSHA 29 CFR 1910.134 which includes medical evaluation, training and fit testing.-Reference CFR 42 Part 84.

Tight-fitting respirators require the wearer’s face to be clean shaven where the respirator’s seal comes in contact with the skin. If the facial hair does not extend far enough to interfere with the device’s seal in any way, or interfere with the function of the exhalation valve, the wearer may wear it with the approval of the respiratory protection administrator.

End-of-service-life is when a respirator no longer works correctly. It is when the filtering medium can no longer provide the expected level of protection from harmful air contaminants, and has reached its capacity for capture and retention of the contaminant. Also when breathing while wearing the respirator becomes too difficult, or when the respirator becomes damaged, contaminated, or the integrity of the respirator is no longer intact.

3. NOISE PROTECTION

There are two rules: First, if you have to raise your voice to talk to someone who is an arm’s length away then the noise is likely to be hazardous. Second, if your ears are ringing or sounds seem dull or flat after leaving a noisy place, then you probably were exposed to hazardous noise.

Anyone regularly exposed to hazardous noise should have an annual hearing test. Also, anyone who notices a change in his/her hearing (ringing or buzzing in the ears) should have his or her ears checked. People who have healthy ears and who are not exposed to hazardous noise should get a hearing test every three years.

Disposable earplugs and reusable ones are not very different in the level of hearing protection. The major difference however, is in how they stand up to wear and tear. A disposable (single use) PU earplug will degrade after first use. PU is not environmental friendly and end up in landfill. Unlike disposables, most reusable ear plugs are made of TPE material. It’s environment friendly product. Other apparent benefits of using a reusable earplug are stated below. It does not require rolling for insertion so it is a good pick incase of soiled hands. Moreover, it doesn’t require the user to wait to let foam recover unlike a disposable one. Plus, the user will be able to easily get multiple wears out of it since reusable earplugs are designed with added durability in mind. They degrade slower than disposable earplugs since they’re typically made with a more resilient design and material to suit washing and hygienic repeat wears.

Earplugs are simple to use, less expensive than muffs and more comfortable in hot or damp work areas. Ear mulls are easier to fit, generally more durable than plugs and have replaceable parts. In areas where noise levels are very high, muffs and plugs can be worm together to give better protection.

That is unlikely for two masons. First, the average ear canal is about 1 inch long. The typical ear plug is between 1/2 to 3/4 of an inch long, 50 even if you insert the entire earplug, it would still not touch the eardrum. Secondly, the path from the opening of the ear canal to the eardrum is not straight. In fact, it is quite irregular This prevents you from poking objects into the eardrum.

Earplugs worm in combination with earmuffs, helmets or communications headsets, typically provide greater protection than either device alone. However, the attenuation of the combination is not equal to the sum of the individual attenuation values For example, at 1000 Hz the combination of a 19 dB plug and a 21 dB muff does not yield 40 dB overall, but rather about 31dB. The simplified solution would be to add 10 dB over the highest device viz 21 dB+10 dB = 31 dB.

It is calculated in Decibel (dB) For every 5 dl increase, the noise is louder by double

NRR-Noise Reduction Rating. It is a laboratory-derived numerical estimate of the attenuation that is provided by the protector.

Attenuation – Attenuation refers to the damping or decrease of noise levels as a result of wearing Hearing Protector Devices (HPDS)

Suitable Hearing Protector -The term “suitable hearing protectors” as used in the provision means protectors that are comfortable to wear and that offer sufficient attenuation to prevent hearing loss.

How to find out the attenuation As per OSHA 1910.95 app B

For Single Protection

When using a sound level meter set on the weighting network

A. Obtain a representative sample of the C-weighted sound levels in the employee’s environment

B. Subtract the NRR from the C-weighted average sound level to obtain the estimated A-weighted TWA under the ear protector Estimated Exposure (dBA) = TWA (dBC) – NRR

Single Protection Example:

1. C-weighted TWA = 108 dBC, ear plug NRR = 32

2. Estimated Exposure = 108-32 = 76 dBA

This hearing protection is considered adequate, as it is below the 85 dBA threshold

For dual protection (ear muffs and plugs are used simultaneously) use the following:

A. Determine the laboratory-based for the higher rated protector (NRRh).

B. Add 5 dB to the field-adjusted NRR to account for the use of the second hearing protector

C. Subtract the remainder from the TWA as follows: Estimated Exposure (dBA) TWA (dBC)-(NRR + 5)

Dual Protection Example

1. TWA=110 dBC, plug NRR=29, and muff NRR=19 dB

2. Estimated Exposure = 110 (29+5)=76dBA

This hearing protection is considered adequate, as it is below the 85 dBA threshold.

Note: If A weighted TWA is set in the sound level meter then deduct value of 7 from NRR Hearing Protection.

4. EYE PROTECTION

Various industrial processes emit IR rays i.e. over luminous transmittance. Also there is very strong UV rays spectrum below luminous transmittance in tropical countries like India. These radiations can cause cataract, retinal bum, painful eye condition, skin cancer around the eyelids etc. The lens of safety spectacles are made up of polycarbonate material which block the entry of UVs radiation into the eyes. Shaded PC lens protect against IR rays.

Selection and use of welding filters are described in IS: 5983-1980.

Manufacturer’s name or trademark and national standard need to be mentioned on temple. Alphabets are used to indicate speciality. For e.g. Ocular “C” for chemically toughened, “V” for High velocity and “M” for molten metals and hot solids.

The type of safety eye protection you should wear depends on the hazards in your workplace. If you are working in an area that has particles, flying objects or dust, you must at least wear safety glasses with side protection (side shield If you are working with chemicals, you should wear goggles If you are working near hazardous radiation (welding, lates or fiber optics) you must use special-purpose safety glasses, goggles, face shields or helmets designed for that task.

Both types of safety lenses meet or exceed the requirements for protecting your eyes.

Glass lenses

• Can not be easily scratched

• Can be used around harsh chemicals

• Can be made in your corrective prescription

• Are sometimes heavy and uncomfortable

• Are likely to fog Polycarbonate lenses

• Are lightweight

• Protects against welding splatter

• Are not likely to fog if coated with AF coating

• Are stronger than glass

• Are more impact resistant than glass

• Are not as scratch resistant as glass

• Are also available as Bifocal or corrective lens

5. HEAD PROTECTION

Head protection products do not have an indefinite life. Helmets should be replaced periodically where user environments are known to include higher exposure to temperature extremes, sunlight or chemicals. If a helmet has been struck by a forcible blow of any magnitude, both the helmet shell and suspension should be replaced immediately, even if no damage is visible.

All safety helmets are marked with month and year of manufacturing. It is recommended that a helmet should not be in use after 5 years from the manufacturing date.