Increase in Fire Incidence in Industrial Zones: A Growing Concern

November 29, 2024

9200

November 29, 2024

9200

In recent years, there has been a noticeable increase in fire incidences across industrial zones worldwide. Whether due to aging infrastructure, human error, or the handling of flammable materials, these incidents pose significant risks to workers, equipment, and overall safety. Among the most dangerous of these fires is the flash fire, an intense and rapidly spreading phenomenon that can erupt in seconds and cause catastrophic damage. Understanding the causes of these fires, implementing effective fire drills, and using proper safety equipment are critical in reducing the impact of industrial fires.

Understanding Flash Fires

A flash fire occurs when a flammable gas or vapor mixes with air in a confined or semi-confined space. If this mixture encounters an ignition source, such as a spark or an open flame, it can ignite almost instantaneously, producing a brief but intense burst of flame. Key characteristics of a flash fire include:

- Rapid Ignition: Flash fires ignite quickly when the fuel-air mixture reaches a critical concentration and encounters an ignition source.

- Short Duration: These fires typically last only a few seconds, but their impact can be devastating.

- High Temperatures: Flash fires can reach extreme temperatures, capable of causing severe burns or igniting other materials.

- Minimal Pressure: Unlike explosions, flash fires do not generate significant pressure waves, though they may increase momentary pressure.

- Risk Factors: Industries like oil and gas, chemical manufacturing, and other industrial operations involving flammable substances are at higher risk of flash fires.

Other Fire Hazards

- Electrical Hazards

Electrical systems are crucial to the functioning of any industrial facility, but if not properly maintained, they can become significant fire hazards. Here are some of the most common electrical risks and their associated consequences:

- Faulty or damaged electrical equipment

- Consequence: Electrical shock, fire, or equipment damage.

- Corrective Action: Regularly inspect and replace damaged equipment and ensure all electrical installations are done properly.

- Overloaded electrical circuits

- Consequence: Fire, electrical shock, or equipment damage.

- Corrective Action: Distribute electrical loads across multiple circuits, upgrade circuit capacity where needed, and continuously monitor usage.

- Poor electrical wiring

- Consequence: Electrical shock, fire, or equipment damage.

- Corrective Action: Regularly inspect wiring, replace faulty lines, and ensure compliance with safety standards.

- Inadequate electrical insulation

- Consequence: Electrical shock, fire, or equipment damage.

- Corrective Action: Ensure proper insulation installation and upgrade insulation materials when necessary.

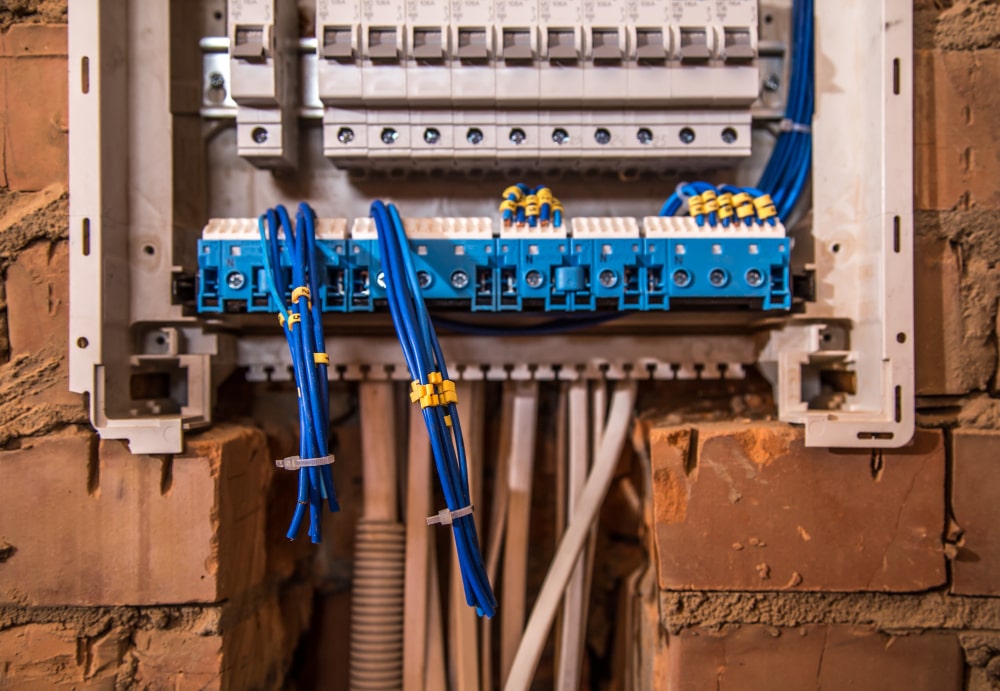

- Unstable or overloaded electrical panels

- Consequence: Fire, electrical shock, or equipment damage.

- Corrective Action: Conduct routine inspections and upgrade panels as needed.

b) Flammable Materials

Many industrial processes involve flammable materials, which pose a significant fire risk if not handled properly. Understanding the consequences and taking corrective action can mitigate these dangers:

- Flammable liquids (e.g., gasoline, paint)

- Consequence: Fire, explosion, or environmental damage.

- Corrective Action: Store flammable liquids in approved containers and ensure proper ventilation in storage areas.

- Combustible dust (e.g., wood, paper)

- Consequence: Fire or explosion.

- Corrective Action: Implement dust collection systems and maintain proper ventilation in workspaces.

- Open flames (e.g., welding, cooking)

- Consequence: Fire or burns.

- Corrective Action: Ensure proper training of workers and use fire-resistant materials in areas where open flames are present.

- Hot surfaces (e.g., equipment, machinery)

- Consequence: Fire or burns.

- Corrective Action: Regularly maintain hot equipment and machinery, and use heat-resistant materials to reduce fire risk.

- Flammable gases (e.g., propane, natural gas)

- Consequence: Fire or explosion.

- Corrective Action: Store and handle flammable gases properly, ensure proper ventilation and monitor gas lines for potential leaks.

c) Ignition Sources

Ignition sources, especially in industrial settings, can turn a manageable situation into a major fire emergency if not handled properly. Below are the most common ignition risks:

- Sparks from electrical equipment

- Consequence: Fire or explosion.

- Corrective Action: Conduct routine inspections and maintenance of electrical equipment, ensuring proper grounding.

- Open flames from cigarettes or lighters

- Consequence: Fire or burns.

- Corrective Action: Enforce a strict no-smoking policy in industrial zones and provide designated smoking areas away from flammable materials.

- Hot particles from welding or cutting

- Consequence: Fire or burns.

- Corrective Action: Train workers in proper safety procedures and use fire-resistant materials in welding and cutting zones.

- Friction or heat from machinery

- Consequence: Fire or equipment damage.

- Corrective Action: Ensure regular maintenance of machinery and use heat-resistant components to prevent friction fires.

- Arcing electrical equipment

- Consequence: Electrical shock, fire, or equipment damage.

- Corrective Action: Regularly inspect and maintain electrical systems to prevent arcing.

d) Fire Spread Hazards

In many cases, fires become more destructive due to their ability to spread rapidly through industrial zones. Minimizing fire spread hazards is crucial for effective fire control:

- Combustible materials near heat sources

- Consequence: Fire or explosion.

- Corrective Action: Store combustible materials away from heat sources and ensure proper clearance between heat-generating equipment and flammable objects.

- Lack of firebreaks or partitions

- Consequence: Fire spread.

- Corrective Action: Install firebreaks or partitions in high-risk areas to contain potential fires.

- Poor housekeeping (e.g., clutter, debris)

- Consequence: Fire or tripping hazards.

- Corrective Action: Maintain a clean workspace by regularly removing clutter and debris to reduce fire risk.

- Inadequate fire suppression systems

- Consequence: Fire spread or damage.

- Corrective Action: Install and maintain fire suppression systems, such as sprinklers and fire extinguishers, in critical areas.

- Uncovered or unsealed electrical outlets

- Consequence: Electrical shock or fire.

- Corrective Action: Cover or seal electrical outlets and ensure proper installation.

General Safety Kit

1. Fire Exit 2. Fire Alarm: 3. Fire Extinguisher: 4. Fire Hose: 5. Emergency Phone: 6. First Aid Kit. 7.Fire Blanket

Fire Drills: A Crucial Safety Protocol

Regular fire drills are essential for ensuring that workers know how to respond quickly and efficiently in industries prone to fire hazards. A standard fire drill should include the following steps:

- Alert and Warning: Sound the fire alarm and announce the drill.

- Evacuation: All personnel should immediately stop their work and evacuate the building via the nearest exit. It’s essential to avoid elevators and stay low to the ground to avoid inhaling smoke.

- Assembly Point: Once outside, proceed to a designated assembly point and check the wind direction to avoid smoke. Ensure all personnel and visitors are accounted for.

- Emergency Response: Contact emergency services and provide details about the fire’s location and extent, if known.

- Fire Safety Team Response: A designated safety team should investigate the situation and provide further guidance to occupants and responders.

- Return to Normal: Once the fire drill is complete, the safety team should debrief participants and identify areas for improvement.

Essential Safety Equipment for Evacuation

Even with well-practiced drills, having the right safety equipment is vital for protecting workers during a fire emergency. Here are some key tools that can make a life-saving difference during evacuation:

- Escape Hood: Designed to protect the wearer’s respiratory system, eyes, and face from harmful fumes, smoke, and gases during an emergency escape. It is crucial for quick evacuation in areas with poor air quality.

2. Self-Contained Breathing Apparatus (SCBA): This equipment provides breathable air in hazardous environments where toxic gases, smoke, or low oxygen levels are present. SCBAs are particularly useful for rescue teams entering a dangerous fire zone or helping others evacuate.

3. Emergency Life Support Apparatus (ELSA): ELSA offers a portable, easy-to-use solution that supplies breathable air for a limited time, ideal for emergency evacuations where quick action is necessary.

To Eliminate or Minimize Fire Hazards

- Conduct regular fire risk assessments

- Train personnel on fire safety and response

- Ensure proper electrical maintenance

- Store flammable materials safely

- Maintain clean and tidy workspaces

- Install fire suppression systems

- Regularly inspect fire extinguishers and alarms

- Develop an emergency evacuation plan

Venus Safety & Health: Your Trusted Partner in Fire Safety

At Venus, we understand the increasing fire risks faced by industrial workers. We provide an extensive range of fire safety products, including Escape Hoods, SCBAs, and ELSAs, to ensure that workers are equipped with the best possible tools during an emergency evacuation. With over 40 years of experience in manufacturing Personal Protective Equipment (PPE), Venus continues to prioritize safety and innovation in hazardous work environments.

By equipping your workforce with Venus products, you’re ensuring their safety and preparedness during any fire emergency, allowing for swift evacuation and protection when it matters most.

Stay safe, stay prepared—with Venus.